Machining

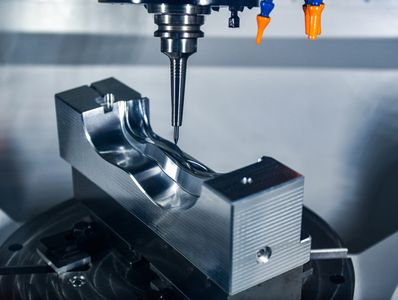

Machining @ Fleetworks

At Fleetworks we offer a comprehensive range of machining services as a trusted subcontracting CNC machine shop. Our capabilities include manual turning and milling, surface grinding, and precision grinding, alongside advanced CNC turning and milling for high-accuracy components.

We also provide wire erosion and spark erosion services, ideal for intricate geometries and hard-to-machine materials. Versatile and adaptable, we tailor our services to meet diverse project requirements across industries.

Whether you're working from detailed engineering drawings or basic sketches, we deliver fast turnarounds and reliable results to your exact specifications.

Welding & Fabrication

Welding and Fabrication @ Fleetworks

At Fleetworks we provide expert welding and fabrication services, offering MIG and TIG welding across stainless steel, mild steel, and aluminium.

With both in-house and on-site capabilities, we support everything from planned maintenance and project work to urgent breakdown repairs. Our workshop is equipped to deliver laser-cut profiles, precision folding, and sheet metal cutting, ensuring high-quality results tailored to your specifications.

Whether you need one-off fabrications or ongoing support, we’re ready to deliver fast, reliable solutions.

Training & Onsite Support

Onsite Support @ Fleetworks

At Fleetworks Engineering, we have a large experienced resource pool. Engineers are specifically targeted at certain operating areas and are tailored to help facilitate with any engineering project.

Labour can be provided to help businesses succeed in implementation of any engineering project, with expert advice given if and when needed to help a project succeed.

With experience of growing and investing in people of all different levels and disciplines, Fleetworks can offer training packages to give your staff the edge within the manufacturing environment.

Packages can be built to accommodate for operatives, line setters, engineering teams and leadership roles to enhance in house expertise and knowledge, so you can utilise you staff to achieve their potential.

On Site Maintenance

On Site Maintenance & Service Contracts

At Fleetworks Engineering, we offer bespoke maintenance services that cater to the unique needs of each client. Our experienced engineers collaborate with you to identify challenges and implement effective solutions that enhance maintenance outcomes, helping implement bespoke maintenance solutions and plans to ensure machinery downtime is limited.

We are dedicated to delivering exceptional service and results that exceed expectations through PPM schedules and exceptional service. For example, we have recently achieved a 20% increase across a production facility by implementing a weekly PPM schedule tailored to the customers needs. Within the schedule, an overhaul on each machine was conducted. This allowed us to engineer the machines back to a high standard, and maintain these high standards through delivering weekly PPM.

Breakdown Specialists

Breakdown Callouts @ Fleetworks

At Fleetworks, we pride ourselves on the speed and ability to achieve a solution in the most demanding of circumstances. Reactive maintenance is undertaken in the event of failure, when an unexpected breakdown causes downtime. This can have a huge effect on manufacturing capability. Having the necessary tools and understanding has allowed us to become a reliable partner in many of our valued clients by acting fast and efficiently.

Fleetworks engineering is here to assist you how ever we can, we are proud to provide telephone and online support to help in the case of breakdowns, in addition to the onsite support which we provide so many of our customers.

Fleetworks Engineering offers the best when it comes to breakdown cover. We handle 90% of all call outs next day with the aim of getting you back into production as soon as possible. As well as having our own in house manufacturing capabilities, we work with a range of suppliers throughout the UK. This means that we can access the spares needed to carry out repairs on site at short notice.

Project Management & Consultation

End-to-End Project Engineering Solutions

We have the ability to provide consultation services by reviewing processes and procedures, tracking +KPI’s and using GAP analysis, to implement new procedures, such as lean manufacturing, and training matrixes.

We can use real time monitoring to collect data on factors such as machine up-time, cycle times, quality and output rates to identify bottlenecks, underperforming equipment, and areas for improvement.

By utilizing Fleetworks as your trusted partner within the productive environment, we can help bring products from concept to full scale manufacturing, managing the entire project life cycle, across all departments.

At Fleetworks Engineering, we provide end-to-end engineering solutions that cover all phases of your projects. Our multidisciplinary team collaborates to ensure seamless integration from concept to completion.

With a focus on quality and efficiency, we help you navigate the complexities of engineering with confidence, delivering projects that exceed expectations. We have undertaken many projects including design, sourcing, installing and implementing procedures for the high end skin care market, meaning the customer is able to manufacture a whole new range of products considered challenging within the industry.